What is fiber concrete and why do we use it?

With the passage of time and the increase in the world’s population, the need for progress in the field of construction, maintenance, and retrofitting of existing structures, as well as the construction of earthquake-resistant structures, is felt more due to the increase in the seismicity of the countries of the world.

Among the new technologies that have a special place in construction, concrete additives, and reinforcing fibers are mainly cement fibers. The use of concrete additives improves the desirable properties of concrete, such as its resistance, and in some cases, by reducing the weight of concrete, it provides engineers with very light materials.

Engineers should know that the structure of concrete and its performance can be changed depending on their needs and expectations of the structure. He designed it in such a way that it is suitable for a specific purpose (for example, to build the foundations of an underwater bridge).

To achieve the desired application and performance of the concrete structure, the global market is offering products to the market at an exponential rate. These products are presented in different forms, one group of these products is the group of cement-reinforced fibers, which are widely produced and presented to the market in both natural and synthetic forms.

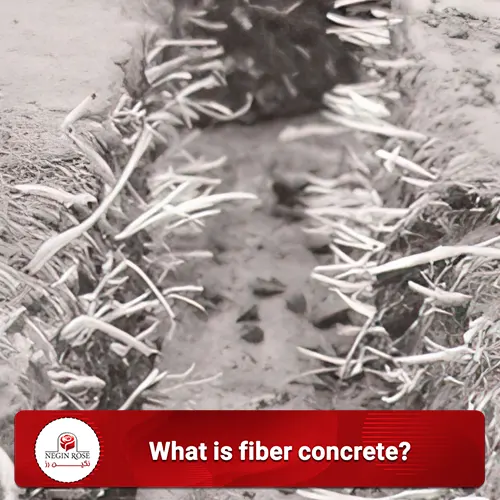

When polypropylene fibers are added to cement and sand mixtures, the weight or volume of the mortar does not increase and its settling does not occur. Concrete fiber is a homogeneous product with a high degree of cohesion and gives concrete the ability to create strong and curved surfaces as a flexible and malleable material. Another feature of PP is its ability to absorb high energy, which does not break apart due to the impact of high energy.

It is interesting to know that in the olden days, clay building materials were dried in the sun and to prevent their brittle texture from cracking, plant and natural fibers such as straw, horse hair, etc. were used. In fact, The combination of PP with cement and concrete mixture is an advanced model of flower straws. In this technology, cement has replaced mud and natural and plastic fibers have replaced straw.

In the beginning, this technology was such that weak cement mortars were reinforced with glass wool. However since the alkaline environment of concrete caused the instability of the glass fiber formula, the addition of conium dioxide was discussed, and in this way tissues resistant to the alkaline environment of cement were produced.

Features of using cement fibers

The use of cement fibers increases the strength and flexibility of concrete, but its application requires high precision and skill. On the other hand, this type of material in building construction provides better engineering solutions to contractors.

As you know, The tensile strength of concrete is much lower than its compressive strength. Tensile strength of concrete is about 10% of its compressive strength. For this reason, the tensile strength of concrete is often neglected in the calculations of concrete structures.

Reinforced concrete is used to compensate for this weakness. Among the materials used for reinforcement are concrete fibers.

One of these materials is a type of polymer fiber called polypropylene fiber. This material, which is widely used in the construction industry, is also known as PP fibers. Adding PP fibers to concrete performs the same work as reinforcement in reinforced concrete.

Concrete fibers maintain the integrity of concrete grains and as a result, increase its tensile strength.

Fibers can be added to concrete in different ways, but it should be kept in mind that the resulting concrete must be uniform in order to prevent material separation. Often, during mixing, concrete takes on a ball shape. The correct calculation of the ratio of dimensions, fiber volume, size, and coarseness is of particular importance. Fiber concrete often requires more cement than regular concrete. In general, it increases the compressive strength. By using this type of material, the flexibility of concrete structures increases significantly.

The reason for using concrete fibers

in concrete and replacing suitable concrete fibers, for example, concrete steel fibers or concrete polymer fibers and concrete glass fibers.

Due to the removal of thermal reinforcement and the replacement of concrete fibers, the current costs of the project are reduced due to the elimination of labor for reinforcement and the reduction of the costs of purchasing reinforcement and concrete steel fibers, the integrated weighing of concrete fibers in the concrete structure and the bearing of sectional and overall pressures in the entire concrete.

Preventing concrete fatigue and creating very high specific resistances, increasing the concrete resistance coefficient in the topics of concrete strengthening in alternating cold and thermal cycles, preventing the attack of sulfates and concrete destructive substances.

For more information and free consultation, you can contact the following numbers.

Advantages of fiber cement (Rosanit)

- Reducing cracking and preventing hairline cracks in concrete

- No settling and no increase in concrete weight

- Eliminating the alkaline environment of concrete

- Improving bending, tensile, shear, and abrasion resistance in concrete

- Reduce material penetration

Applications of cement fibers (Rosanit)

- Use in concrete

- Use in cement and plaster mixtures

Rosanite (cement) fibers are produced with cut lengths of 6, 12, and 18 mm for concrete use. The following table shows the technical characteristics of these fibers.

|

Properties

|

Value

|

Unit

|

|---|---|---|

|

Raw material

|

pp 100%

|

-

|

|

Specific properties

|

Concrete fber

|

-

|

|

Type of finish

|

Hydrophilic

|

-

|

|

Melting point

|

160 - 170

|

°C

|

|

Softening point

|

140 - 150

|

°C

|

|

Specific gravity

|

0/91

|

g/cm³

|

|

Count

|

2/2

|

dTex

|

|

Diameter

|

17 - 19

|

µ

|

|

Tenacity

|

2/5 - 3/5

|

g/den

|

|

Elongation

|

80 - 100

|

%

|

|

O.P.U finish

|

0/6 - 1

|

%

|

|

Sinking time

|

3 - 5

|

sec

|

|

N.C.D crimp

|

0

|

crimp/cm

|

|

Cut length

|

6 - 12 - 18

|

mm

|

|

Static load

|

1/2 - 1/5

|

KV/m

|

Reviews

There are no reviews yet.